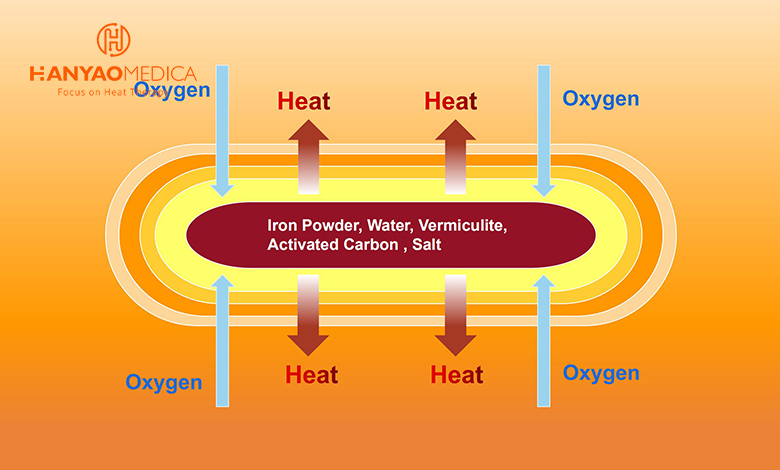

Air-activated Warmers/Patches is based on the exothermic principle of iron oxidation: a process in which iron and oxygen in the air react chemically under the action of various catalysts to convert chemical energy into thermal energy. So as a key factor, how does quality of iron powder affect Warmers/Patches?

Currently, Warmers/Patches of varying quality are popular on the market. One of them, we call this type Q-Warmer here. Q refers to quickly. After opening the package of this type of product, the temperature will rise to the highest level in a short period of time, and then drop sharply. The heating time is short, but it gives people an impact of high temperature. Another type of Warmers/Patches we called S-Warmer here, S stands for Stable. The characteristic of this kind of warm patch is that it not only heats up quickly, but also the overall temperature change is very stable, without a sharp rise and fall process.

The difference between these two types of Warmers/Patches is that they use different qualities of iron powder. The reason why Q-Warmer happens like this is because it uses poor iron powder with low purity and many impurities. It reacts violently with oxygen. Once the heat is released, the temperature will drop rapidly. The iron powder used by S-Warmer is of better quality, with higher purity and less or almost no impurities. Therefore, this type of iron powder reacts mildly with oxygen and has high stability. But the price of such iron powder is also very high.

Then, do you know what impact these two types of Warmers/Patches will have on us during use? Please follow the next news: Chapter 2-What are the different effects of using Patch/Warmer with different qualities of iron powder?